The Mining Process

1. Mining – Open Pit and Underground — To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers. Dump trucks haul the rock to the primary crushers in the open pit or to the ore stockpiles from underground.

2. Crushing — The primary crushers located at the open pit mine site, receive ore and waste at separate times. They break the larger rocks down to a size suitable for transport on the conveyor belt.

3. Transport — A rubber belted conveyor transports the ore and waste rock from the open pit, approximately two kilometres, via a tunnel through Union Hill, to the mill and waste rock embankments. Large electromagnets remove any steel debris excavated from the old Martha Mine workings.

4. Grinding and Sizing — Ore from both open pit and underground is stockpiled separately at the mill before being fed into a semi autogenous grinding (S.A.G.) mill with lime, water and steel balls. The larger particles from this mill are returned to the S.A.G. mill for more grinding. The finer particles receive more grinding in a ball mill, and are size classified to give a final product of 80% < microns.

5. Leaching and Adsorption — A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules, which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

6. Elution and Electrowinning — The loaded carbon is fed into an elution column where the bullion is washed off. The barren carbon is recycled. The wash solution—pregnant electrolyte—is passed through electrowinning cells where gold and silver is won onto stainless steel cathodes.

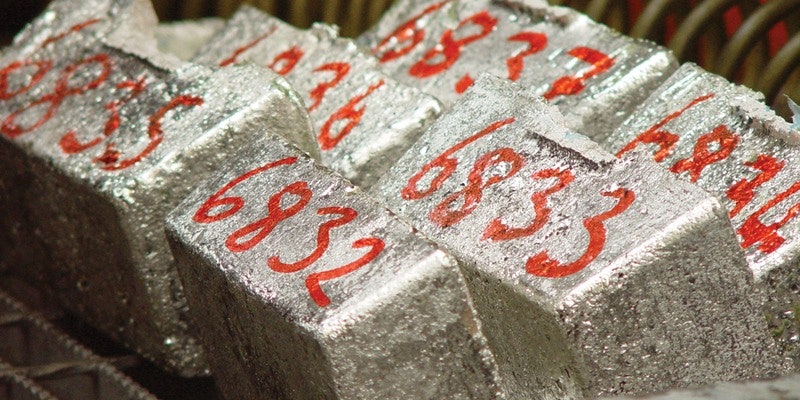

7. Bullion Production — The loaded cathodes are rinsed to yield a gold and silver bearing sludge which is dried, mixed with fluxes and put into the furnace. After several hours the molten material is poured into a cascade of moulds producing bars of doré bullion.

8. Water Treatment — Some water from dewatering the mine, from the embankment under-drains and decant water from the tailings pond is recycled for use in the grinding circuit. Excess water is pumped to the water treatment plant and treated to the required standards before discharge into the Ohinemuri River.

9. Tailings Disposal — Waste rock from the open pit mine is used to build the embankment structures. The embankments retain the tailings slurry in a pond where solids settle and compact. Water is decanted off and used in the process plant or treated before it is discharged.

Assaying

Samples of rock from the mines are sent to the SGS laboratory in Waihi to determine the gold content.5

Crushing and Conveying

Rock is crushed and then transported to the processing plant and waste rock embankments by an overland conveyor.3

Gold Refining

Doré bullion from Waihi Gold's mines is delivered to the refinery at the Western Australian Mint.1